These fans are very well known in regard to Ventilation and Air Conditioning applications. These are provided with a medium speed impeller having Double curved Backward discharge tip blades and stationary directional (Guide Vanes) inlet vanes.

These fans are of Limit Load characteristics, and provide quieter operations and better efficiency. These are built in a complete line of sizes which conform with a a letter segment of Industrial air handling requirements.

‘LL’ and ‘LD’ impellers have deep wide blades which are more efficient and of extra rigid nature because of their double curved feature. Due to their extra width and full open tip, the operational noise level is quiet low compared to other designs of Backward curved fans.

The inlet guide vanes provided at the inlet cone of the fan reduce turbulence in air at fan entry and so as the noise level. As it moves the air in the direction of the impeller vanes. The operational efficiency of the fan is greater because of this unaccounted work done by vanes. Also these serve as an effective safety guard without the obstruction to air flow encountered with a screen.

These vanes are particularly valuable to the user when sharp bends and obstructions on the inlet tend to disturb the proper entry of air to fan rotor.

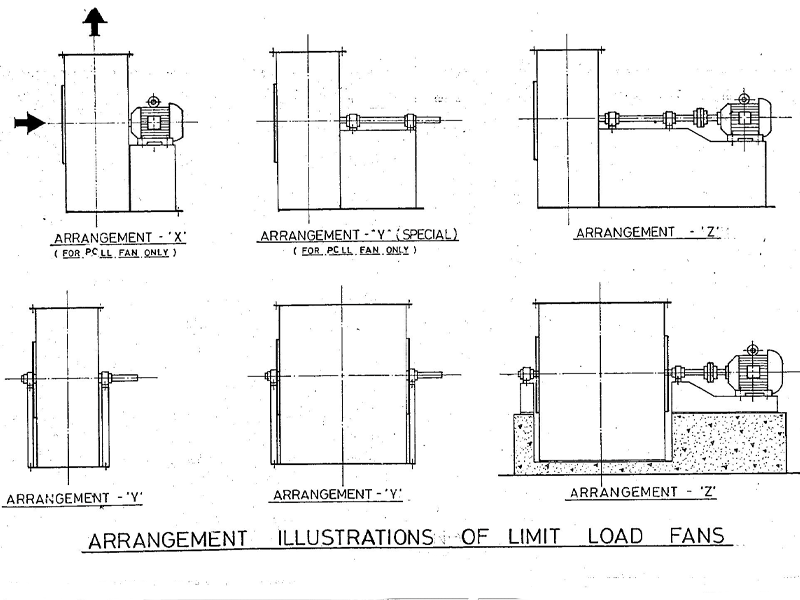

Standard Arrangements for ‘LL’ and ‘LD’ Fans

The following fan arrangements are those generally used. Fans are designated as CLOCKWISE or ANTICLOCKWISE, if when facing the drive end shaft the direction of wheel rotation is clockwise or anti-clockwise. The discharge orientation of a fan is determined by the direction of the line of air discharge and it’s relation to the fan shaft for every complete 90 Deg of rotation. All other discharge orientations are intermediate discharges and are indicated as ANGULAR DISCHAGES.

ARRANGEMENT-X

Direct connected ‘LL’ fans only (SISW) in CLASS-I and II construction are provided in this Arr. with a limitation up to SIZE 93. The impeller is directly keyed in to the drive motor shaft. A box type sheet steel fabricated pedestal attached to the fan housing supports the motor.

ARRANGEMENT-Y

This arrangement fans are furnished in ‘LL’ (SISW) design only. The wheel is overhung on extended shaft. Two bearings are mounted on sheet steel pedestal and the opposite end of shaft extended to receive pullet of drive set.

ARRANGEMENT-Y (Spl.)

These Arr. fans are furnished in both ‘LL’ and ‘LD’ (SISW and DIDW) designs and in all sizes. A bearing is furnished on each side of the fan casing and pulley is overhung. However, the larger sizes (beyond SIZE 93) are furnished with substantial fan side bracings supporting the bearing; or sometimes with independent pedestal blocks.

ARRANGEMENT-Z

Direct driven fans in CLASS-I and II construction both in ‘LL’ and ‘LD’ (SISW and DIDW) designs and in all available sizes are provided in this arrangement. Two available sizes are provided in this arrangement. Two fan bearings, extended shaft and MS motor sub-base are provided.